Enhance Your Device with a High-Quality Membrane Switch for Superior Performance

Enhance Your Device with a High-Quality Membrane Switch for Superior Performance

Blog Article

Discover the Versatile Uses of Membrane Layer Change in Modern Electronics

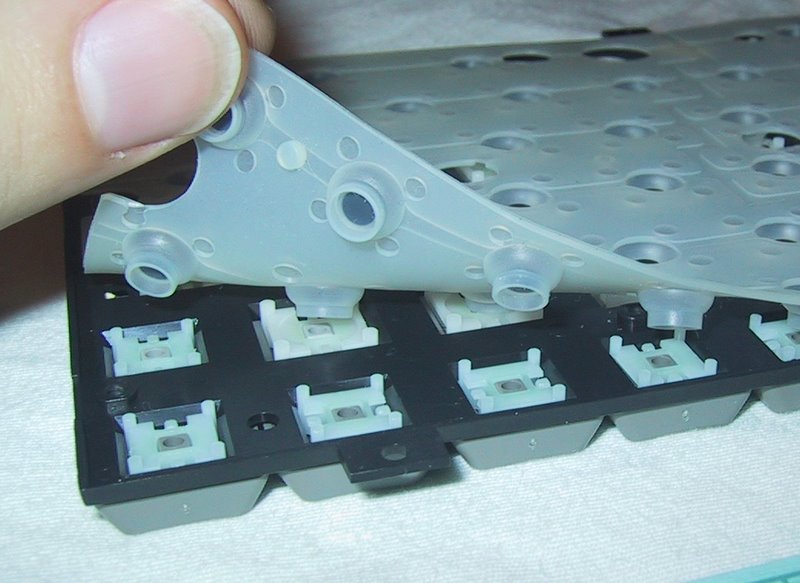

In the world of modern-day electronic devices, the application of membrane layer buttons is incredibly extensive, extending from streamlined consumer gizmos to crucial medical gadgets. These thin, flexible user interfaces not only enhance tool operation with their responsive responsiveness but also substantially boost longevity by resisting ecological risks like moisture and dirt. As sectors remain to develop, the combination of membrane switches in devices style is pivotal, encouraging not just to satisfy however surpass the strenuous demands of both capability and aesthetic charm. Discover a lot more about exactly how these components are shaping the future of innovation.

Exploring the Role of Membrane Changes in Customer Electronics

Why are membrane changes so common in customer electronic devices? Membrane layer buttons are economical to manufacture, making them an appealing choice for high-volume production common in customer electronics.

Additionally, these buttons are recognized for their longevity and reduced maintenance. They are resistant to dirt, moisture, and dirt, which improves the long life of the electronic gadgets they are utilized in. This dependability is important in daily customer items that undergo regular usage. In addition, their adaptability in design enables customization in aesthetic appeals and capability, satisfying the certain demands of different electronic tools. From microwave stoves to remote controls, membrane buttons give a sensible, user-friendly interface that sustains the dynamic nature of consumer electronics.

Membrane Layer Switches in Medical Gadgets: Enhancing Interface

Membrane buttons likewise play a significant function in the realm of clinical devices, where they improve customer interfaces with their unique benefits. The smooth, covered surface of membrane layer changes enables for easy sanitation, decreasing the threat of published here contamination and spread of pathogens.

Membrane layer switches additionally add to the durability of clinical tools. Their resistance to liquids and contaminants makes sure that vital equipment stays operational in numerous professional setups, consisting of surgical procedures where direct exposure to fluids prevails. This resilience, combined with responsive comments and inconspicuous layout, makes membrane layer changes an indispensable part in boosting the efficiency and safety of medical tool user interfaces.

The Impact of Membrane Layer Switches Over on Industrial Devices Layout

In the world of industrial equipment style, the consolidation of membrane layer switches has actually noted a considerable evolution. These switches have changed just how manufacturers approach interface capabilities, offering a blend of sturdiness and convenience that is essential in severe environments. The slim profile of membrane layer switches over enables more small machine styles, while their resistance to dust, water, additional reading and chemical impurities makes them perfect for commercial setups. This versatility has actually promoted the advancement of devices that is not only more durable but also simpler to maintain and clean, thus decreasing downtime and operational prices.

Furthermore, the customizability of membrane switches enables developers to incorporate details responsive comments and graphical overlays that improve the individual experience and increase performance. This assimilation sustains operators in accomplishing precision control over intricate equipment. The general effect is a considerable enhancement in the performance, integrity, and user-friendliness of commercial tools, straightening with the boosting needs for technical improvement and operational efficiency in contemporary markets.

Final Thought

Membrane switches have transformed modern electronics, using smooth, long lasting, and personalized interfaces throughout different sectors. This innovation not only meets the demanding conditions of different fields however also significantly enhances customer experience, making membrane layer switches a foundation of modern digital design.

In the realm of modern electronics, the application of membrane layer buttons is incredibly comprehensive, covering from sleek consumer devices to important medical devices.Why are membrane switches over so common in customer electronics? Membrane layer buttons are affordable to make, making them an appealing option for high-volume production normal in consumer electronics. From microwave read this post here ovens to remote controls, membrane layer buttons supply a functional, user-friendly user interface that sustains the vibrant nature of consumer electronic devices.

Report this page